PRODUCTS

Product list

Dehumidifier

Item No.:

003

Dehumidifier

Home appliance

Product details

Overview

Adsorption rotary dehumidifier is recognized as one of the preferred technologies to replace CFC's compression refrigeration dehumidification in the twentieth century due to its significant energy saving and environmental protection advantages. The rotary dehumidifier can quickly, simply and effectively reduce the air humidity, and effectively solve the dehumidification fields such as normal temperature and low humidity, low temperature and low humidity that cannot be achieved by other refrigeration methods, especially the air dew point can reach -70°C after combined treatment The following: and can use industrial waste heat, waste heat, solar energy, natural gas and other low-grade thermal energy as renewable energy, no environmental pollution, low energy consumption.

Widely used in food, medicine, electronics, electrical appliances, chemical industry, national defense, printing and other industries with humidity requirements. In areas with high temperature and high humidity, the adsorption rotary dehumidifier will exert its unique advantages and bring huge economic benefits to enterprises.

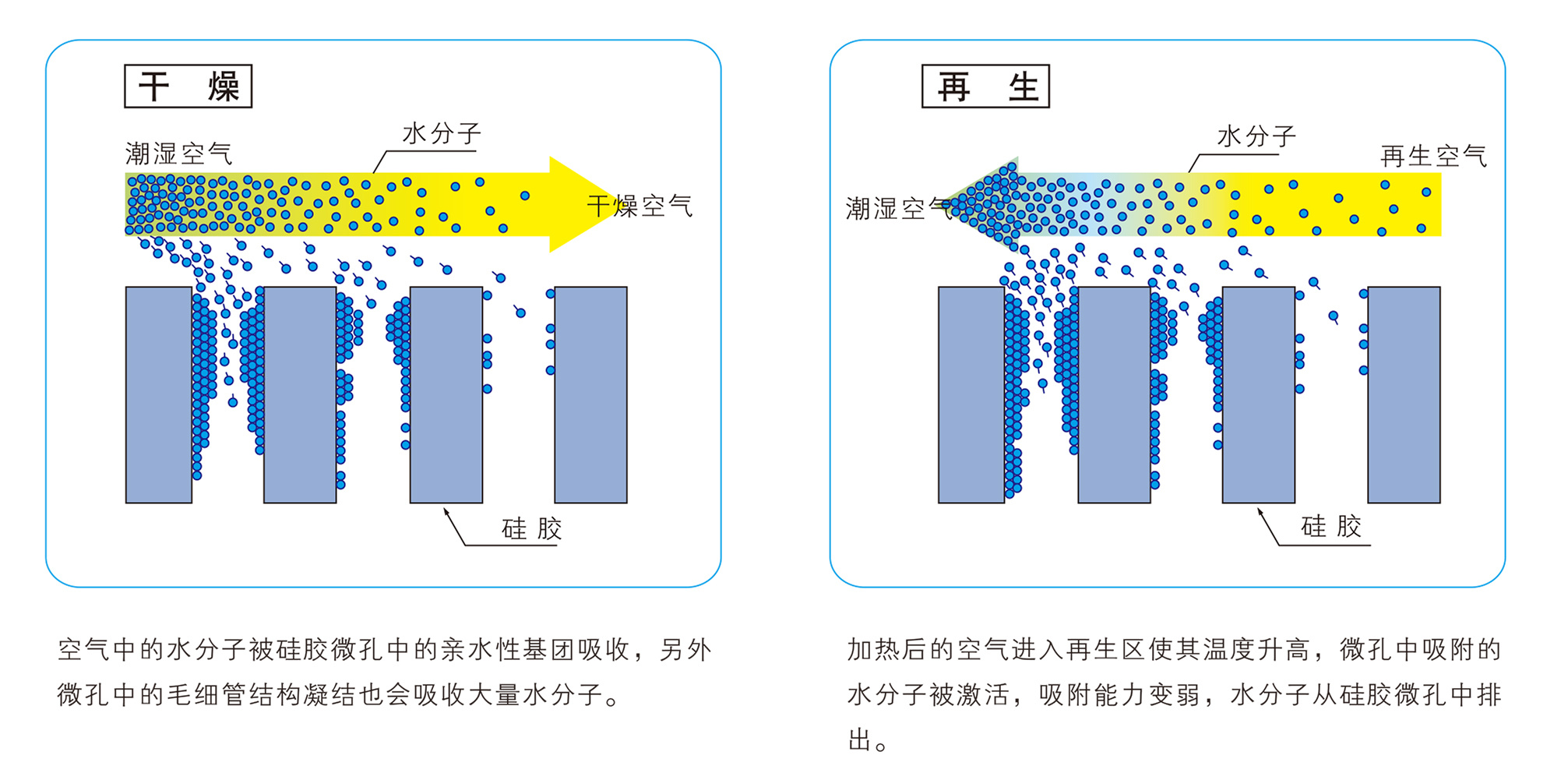

The working principle of dehumidifier rotor adsorption and desorption

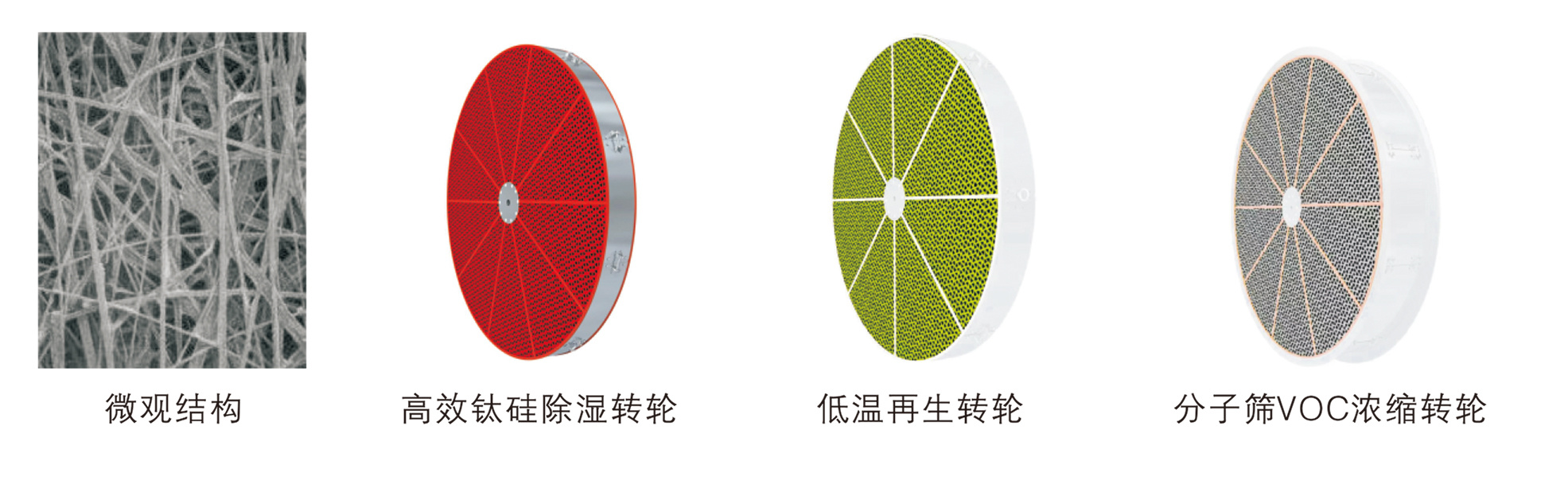

Dehumidifying Wheel

"Fengxing" dehumidifier adopts a world-class patented high-efficiency runner; the runner adopts a patented technology: with an inorganic binder, the glass fiber is processed into a honeycomb Under high temperature combustion, all organic substances are transferred, and then the runner of the honeycomb matrix is fused with special silica gel (metal silicate) through a polymerization reaction, so it not only has good heat resistance, but also can be applied under any humidity conditions ; Strong dehumidification ability, no dehumidifier loss, non-toxic, non-corrosive, ensuring long-term safe and stable operation; because the runner increases hydrophilic groups and micropores to absorb more water, according to air conditions , the drying capacity is 20% ~ 30% higher than other silica gel runners.

The molecular sieve rotor uses special synthetic zeolite as hygroscopic agent to implant into the glass fiber matrix. Because zeolite has small pores and strong heat resistance, this rotor is suitable for Low dew point conditions, or used to treat air containing volatile organic compounds such as ethylene glycol, acetaldehyde, etc.; regeneration air up to 220°C can be used for runners, and all runners are basically free of polymerization; this rotation The wheel is made of special synthetic zeolite crystallized on glass fiber through a special chemical reaction. According to the air flow conditions, a single wheel can reach -80°C D.P.

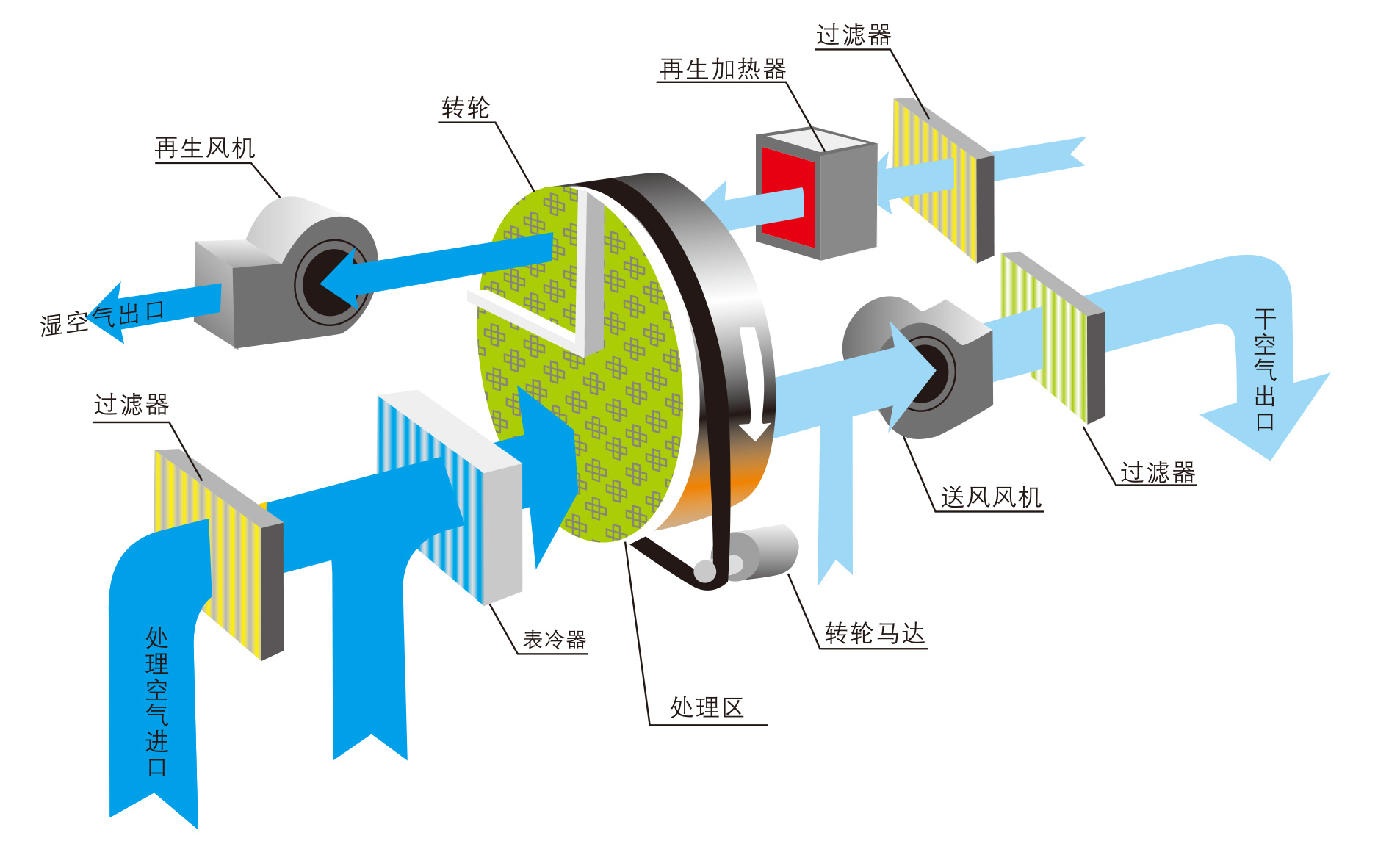

Basic structure and working principle of dehumidifier

The core component of the rotary dehumidifier is a honeycomb runner, which is composed of a special ceramic fiber carrier and active silica gel; the two sides of the runner are made of special sealing devices Divided into two areas: treatment area and regeneration area.

When the humid air that needs to be dehumidified passes through the treatment area of the runner, the water vapor of the humid air is adsorbed by the active silica gel of the runner, and the dry air is sent to the treatment area by the treatment fan. The runner that rotates slowly and carries saturated water vapor enters the regeneration area; the high-temperature air blown in the reverse direction in the regeneration area causes the water adsorbed in the runner to be desorbed and discharged to the outside by the fan, thereby The runner restores the ability to absorb moisture to complete the regeneration process.

The wheel rotates continuously, and the above-mentioned dehumidification and regeneration are carried out over and over again, so as to ensure the continuous and stable dehumidification state of the dehumidifier.

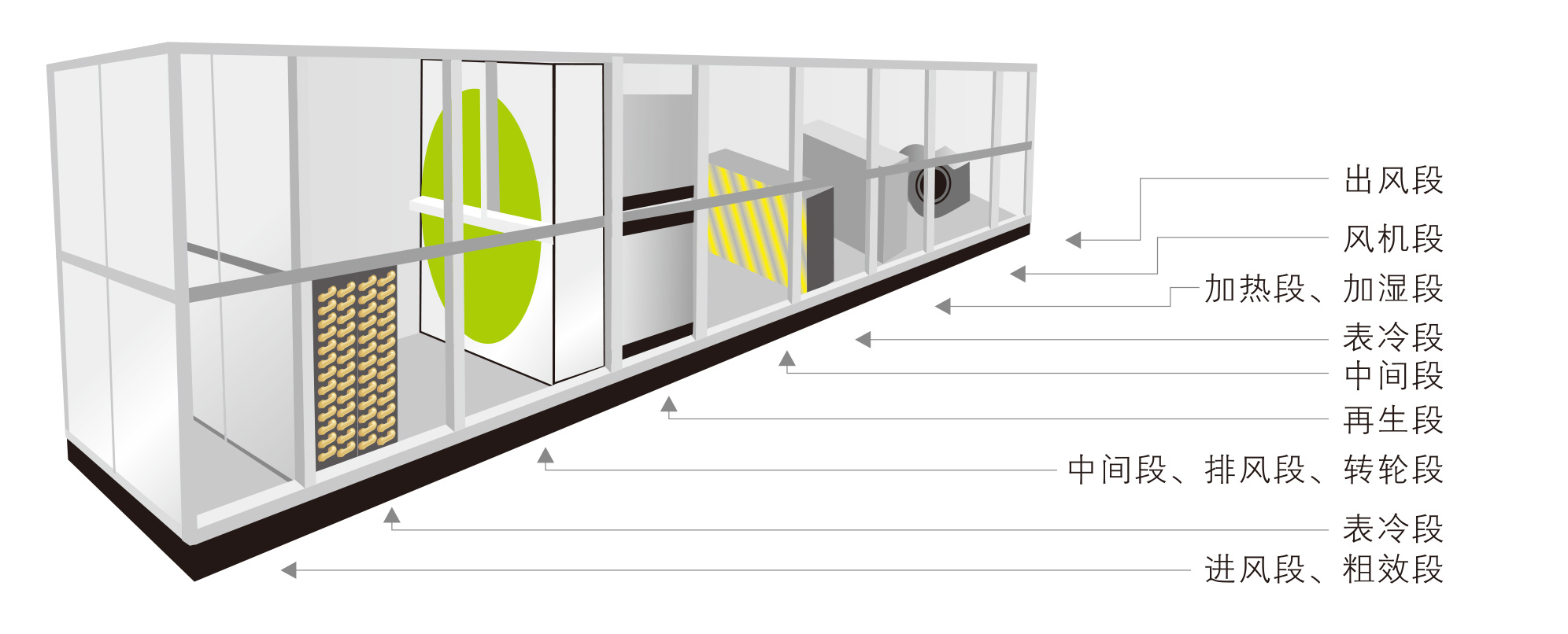

Structural perspective view of a combined dehumidifier without an intercooler

Refrigerator Air Conditioner FXA

Application scenarios: electronics, food, medicine, biochemical industry, military industry and warehouses, where the relative humidity is above 45%.

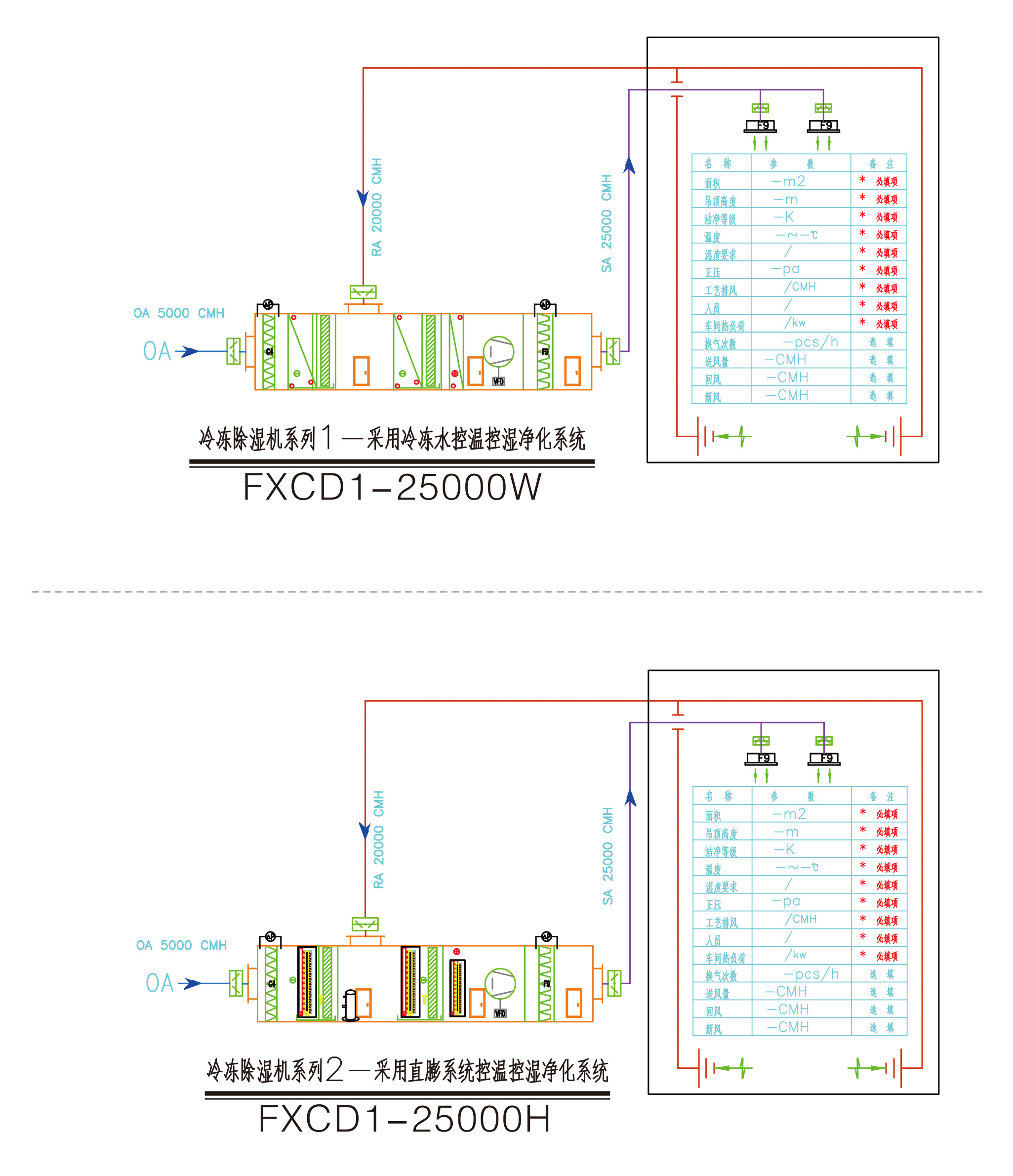

Refrigeration Dehumidifier FXCD

Application scenarios: electronics, food, medicine, biochemical, military, underground engineering and warehouses, where the relative humidity is above 45%.

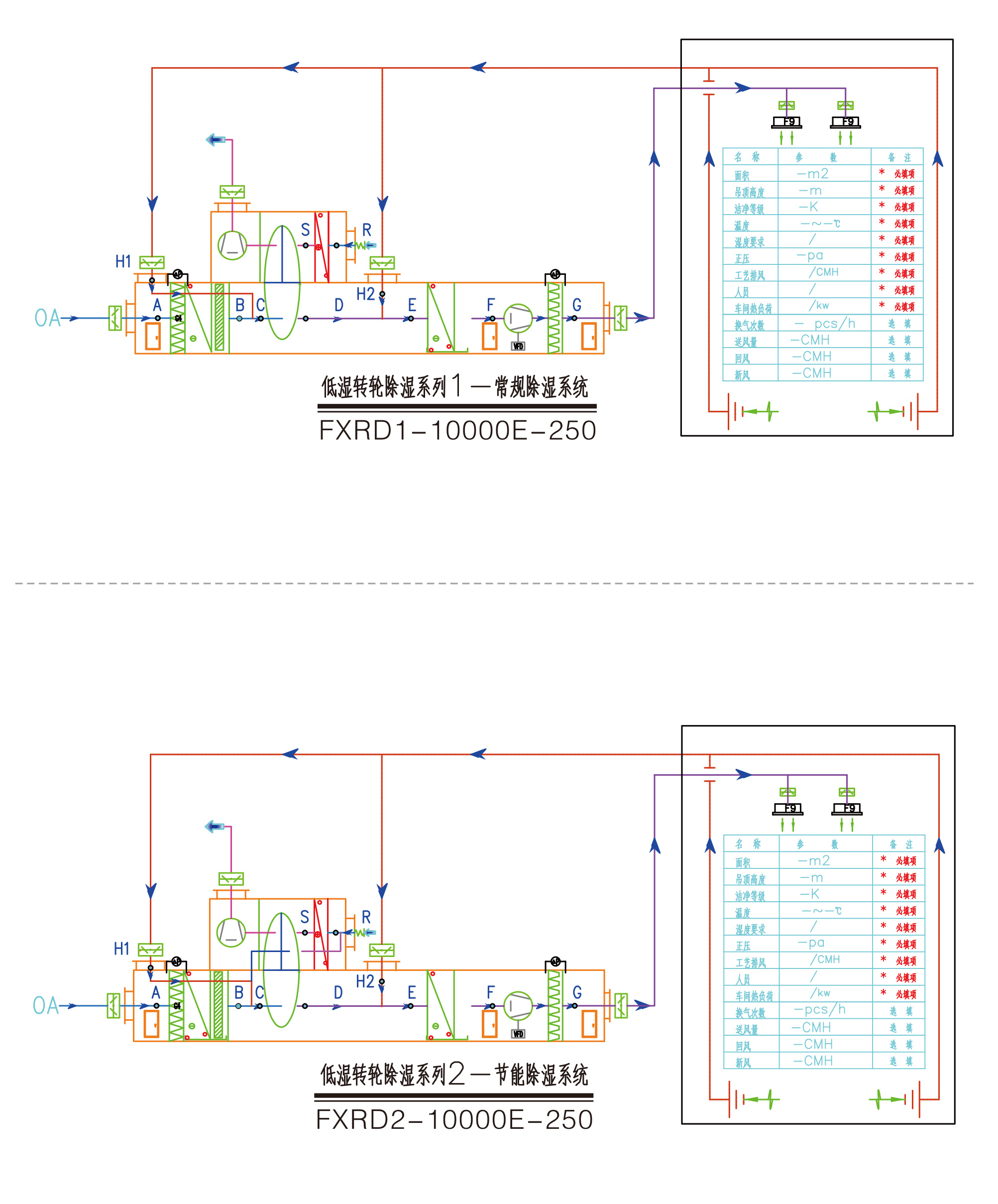

Rotary Dehumidifier FXRD

Application scenarios: food, medicine, biochemical industry, military industry and warehouses, where the relative humidity is above 5%~45%.

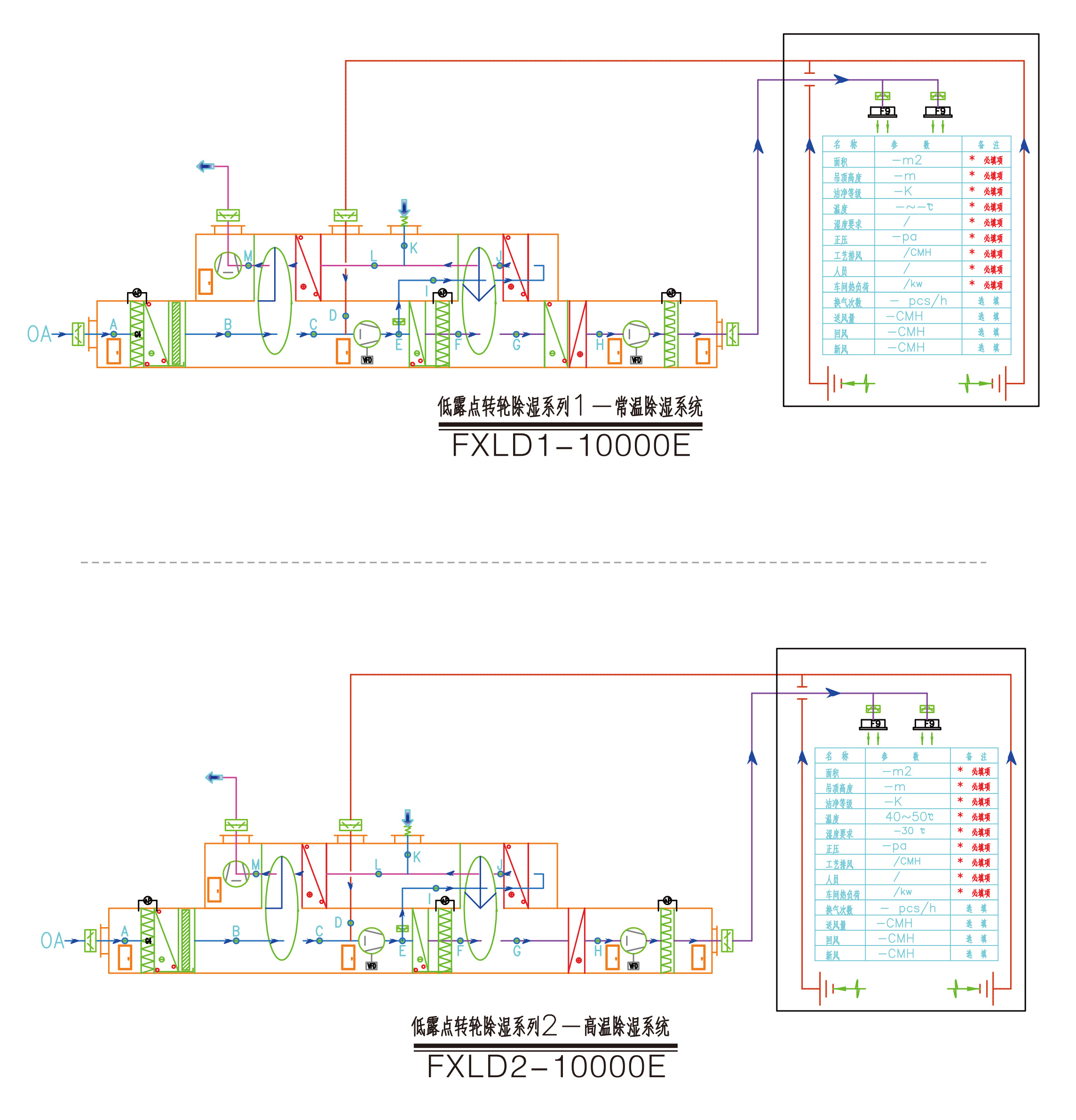

Low Dew Point Rotary Dehumidifier FXL .D

Application scenarios: lithium battery, electronics, biochemical, military and hazardous chemicals warehouses, where the relative humidity is below 5% to -70% dew point.

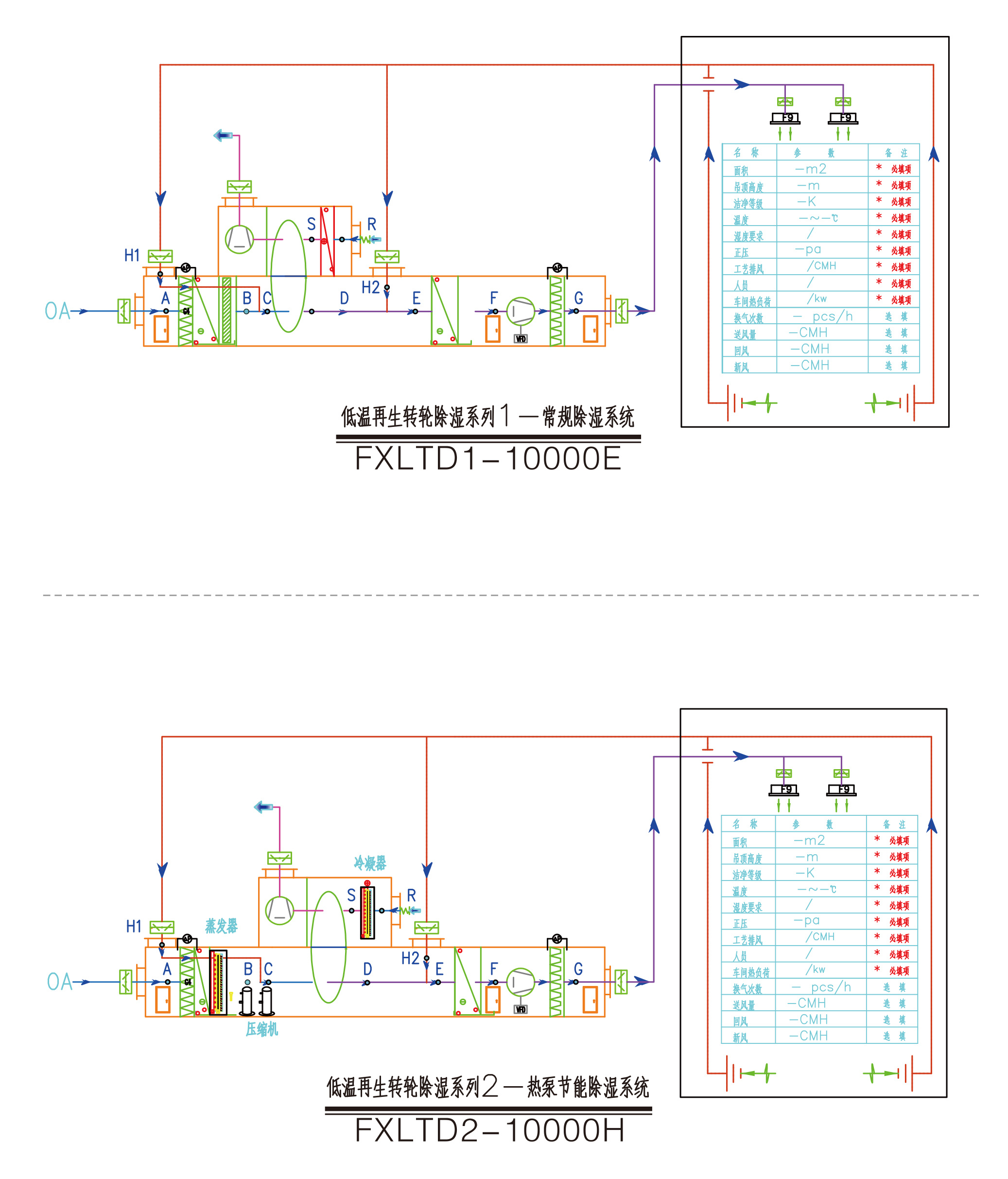

Application scenarios: exhibition centers, gymnasiums, electronics, food, medicine, biochemical, military and warehouses, where the relative humidity is 15%~70%.

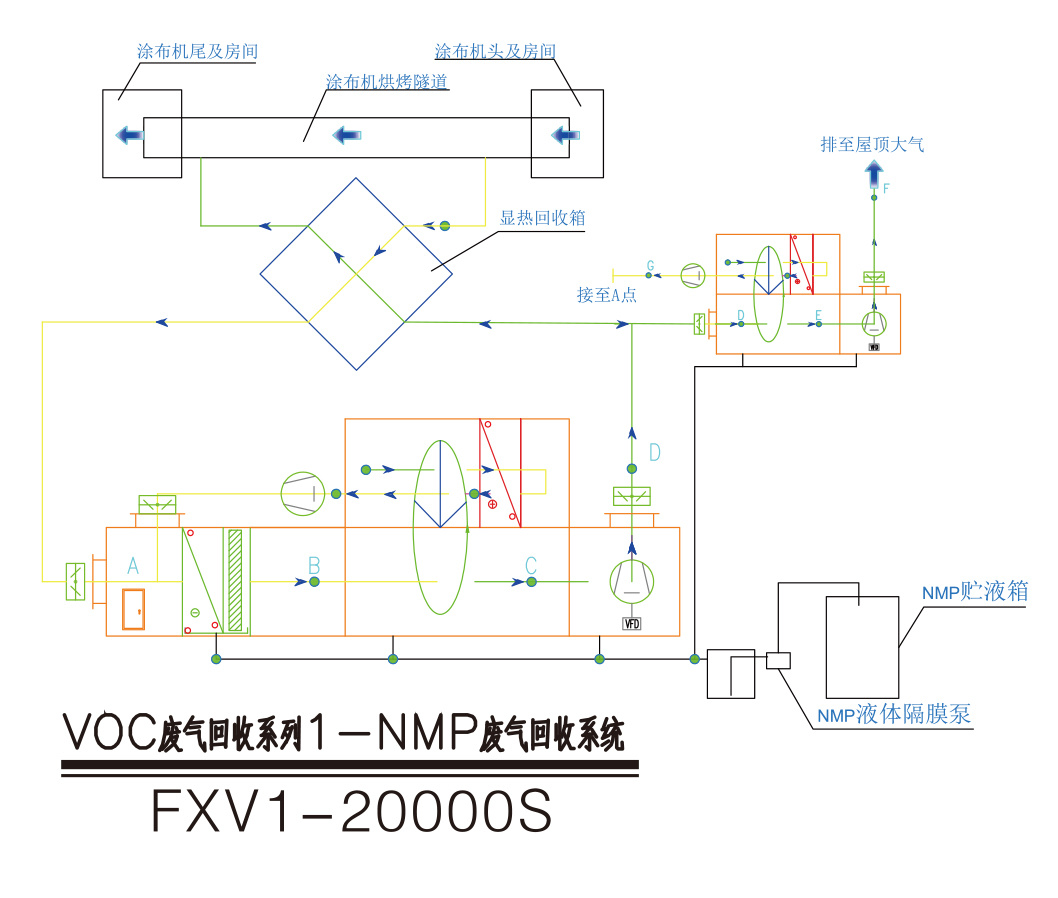

VOC organic solvent recovery unit FXV

Fengxing Environment NMP recycling system: The battery has stricter requirements for the dehumidification system, and also puts forward new requirements for the NMP recycling system. NMP-methylpyrrolidone, whose boiling point is 200C, is widely used as an organic solvent in the lithium battery manufacturing industry due to its high flash point and good safety.

The NMP recovery device developed by Fenghang Company combines cooling condensation technology and rotor adsorption technology to realize continuous NMP solvent recovery and air purification. The equipment is compact and reliable in operation; NMP can be recovered by combining common circulating cooling water and chilled water according to different requirements of users; NMP can also be recovered by combining common circulating cooling water and chilled water with recovery runners. The hydrophobic molecular sieve runner selected in the equipment has excellent adsorption performance, which is conducive to the concentration of NMP in the recovery process and improves the recovery efficiency; and is conducive to the humidity control of the drying air of the coating oven.

Fengxing Environmental NMP recovery system has reasonable process and reliable operation, and the concentration discharged into the atmosphere can reach 20 PPM, or even less than 10 PPM.

Fengxing Environment NMP recycling system has four main functions:

1. Recycling the exhaust heat of the coating machine;

2. Recycle and recycle NMP in the exhaust air of the coating machine;

Third, it is beneficial to the humidity control of the drying air of the coating oven.

Fourth, the amount of exhaust gas discharged is small and meets the requirements of environmental protection.

Application scene field: organic solvent NMP waste gas recovery system applied to new energy lithium battery pole piece coating process.

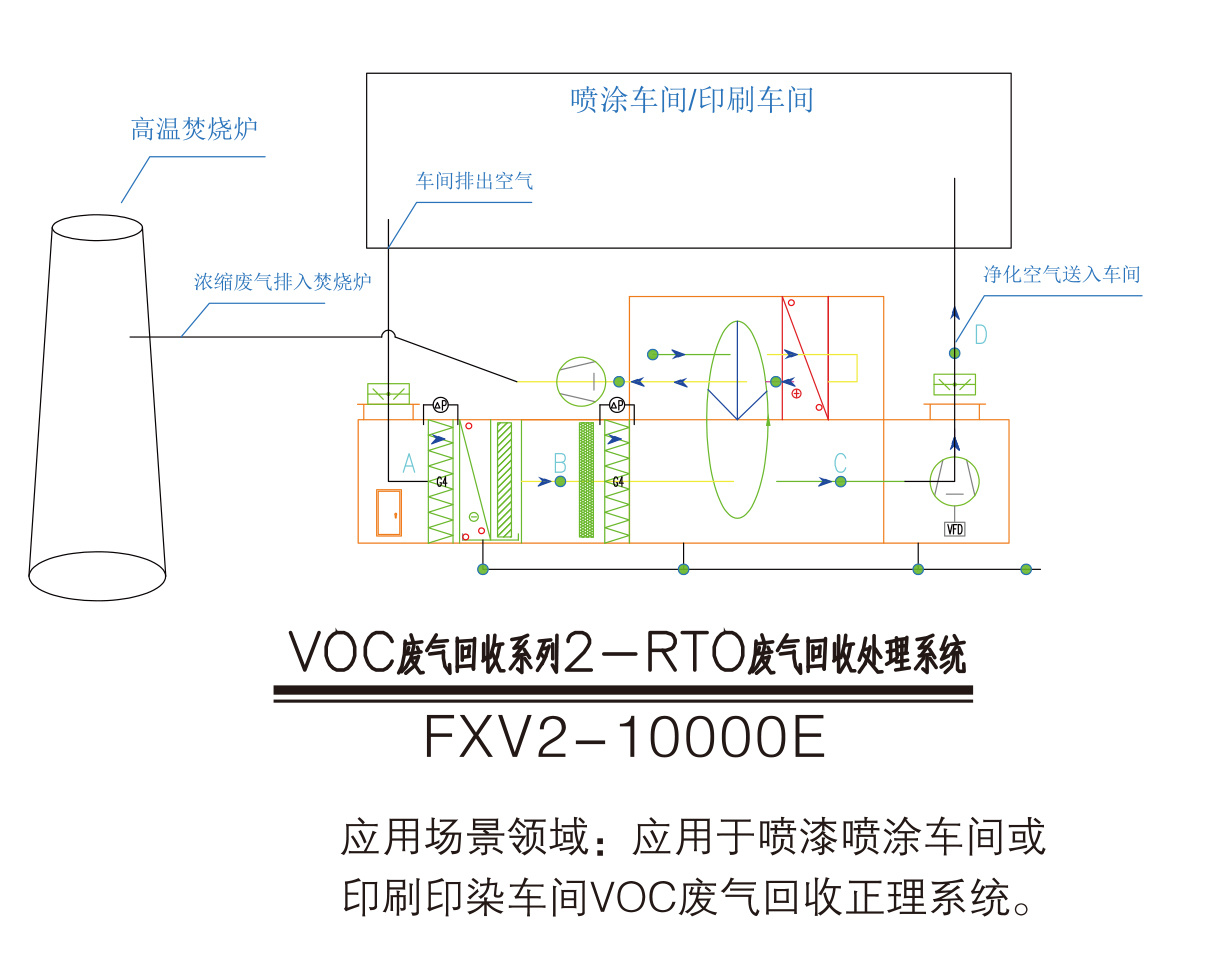

VOC is the English abbreviation of volatile organic compounds (volatile organic compounds). After SO2 and Freon, the pollution of volatile organic compounds (hereinafter referred to as VOC) has become another concern of all countries in the world. One focus, most VOCs are toxic and will cause people to suffer from cumulative respiratory diseases. Under the sudden action of high concentrations, sometimes acute poisoning or even death may occur. Some VOCs can cause cancer.

Most VOCsBoth are flammable and explosive, and are prone to fire or explosion when they are discharged at high concentrations. VOCs have become a worldwide public hazard. Developed countries continue to amend laws and repeatedly reduce the emission concentration of VOCs.

VOC degradation method

- Active adsorption method

- Induced wind high-altitude discharge method.

- Combustion treatment

- Absorptive degassing

- Condensation Collection

- Bioprocessing

- Using the alternative HAP solvent method

Application scene field: It is used in the VOC waste gas recovery system of painting workshop or printing and dyeing workshop.

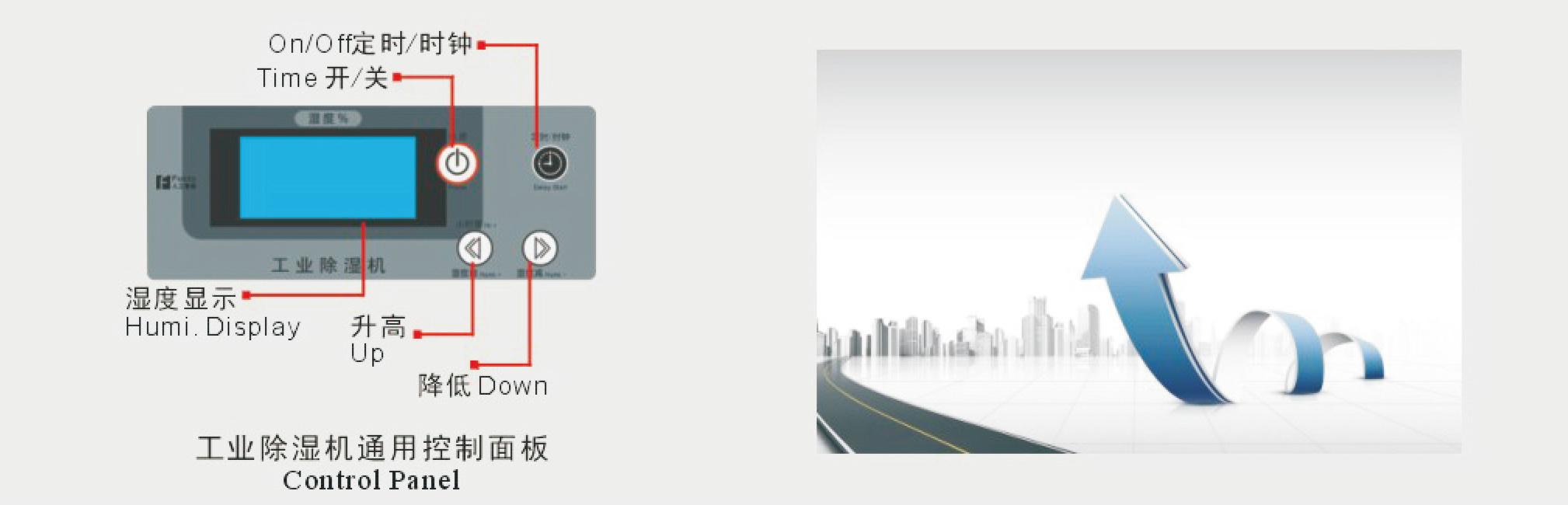

Functions and Features:

- Full computer LCD display

- Error code display

- Free humidity settings

- Compressor three-minute delay protection

- Universal wheels on the feet, easy to move

Note: Industrial dehumidifiers above CD-15S do not have universal wheel moving function

Parameter list

| Model | Dehumidification | Applicability Floor height 2.6 min. |

Power | Rated Input Power | Defrost style | circulation volume | Drainage | Noise Index | Use ambient temperature | Humidity adjustment range | Compressor Protection |

Volume | Net Weight |

| CD-7S | 7Kg/h | 140-220m² | 380V/50Hz | 2820W | Auto | 2000m³/h | Hose continuous drain | ≤60dB(A) | 5-38℃ | 40% to 90% +5% |

Three points Bell extension time |

600× 410 ×1612mm |

89 kg |

| CD-8.8S | 8.8Kg/h | 180-300m² | 4120W | 250Om³/h | 770x470 ×1730mm |

105kg | |||||||

| CD-10S | 10Kg/h | 200-400m² | 4900W | 2800m³/h | 770×470 ×1730mm |

113kg | |||||||

| CD-15S | 15Kg/h | 400-550m² | 7200W | 4000m³/h | ≤70dB(A)| | 35% to 95% ±5% |

1220×520 ×1750mm |

220 kg | |||||

| CD-20S | 20Kg/h | 550-800m² | 10000W | 5600m³/h | 1220×520 x1750mm |

240kg | |||||||

| CD-30S | 30Kg/h | 800-100cm² | 15000W | 8000m³/h | 10% to 90% 5% |

730x1750 x200omm |

380kg | ||||||

| CD-40S | 40Kg/h | 1000-1500m² | 22000w | 11200mn | 730×1850 ×210omm |

430 kg |

Note: The above product technical parameters are subject to change without prior notice (Test standard Condition T=30 °C/ RH80% )

Special reminder to users:

- Using a microcomputer-controlled dehumidifier, the humidity sensor is a precision instrument. Using it in an environment with strong corrosive gas and large dust will cause the instrument to malfunction.

- Before using the dehumidifier, please read the manual carefully to avoid damage to the dehumidifier caused by improper operation.

- This machine does not have explosion-proof and anti-corrosion functions, and it is strictly prohibited to use it in environments with special requirements such as flammable, explosive gas, dust, chemical products, and biological products.

- The power supply of the machine must be grounded and protected by a circuit breaker with a 220V/50HZ AC power supply (380V/50HZ for CD industrial series dehumidifiers) The power cord must match the power of the machine,

- The rated current of the fuse is set according to the requirements of the user manual.

- The machine should be rested regularly when the machine is running for a long time. The machine should clean the filter screen regularly. If the dehumidifier is not used for a long time, it should be well protected from moisture and dust.

- If the pictures and parameters of this album are different from the physical machine, the physical machine shall prevail.

Notes:

- It should be used on a firm and flat ground to avoid accidents such as abnormal noise and water leakage from the machine.

- Check whether the voltage of the power supply is consistent with that of the unit. Do not use the same power supply with other electrical appliances.

- Do not place the machine near a heat source to avoid increasing power or causing accidents.

- When moving or carrying the machine, do not tilt the machine more than 45 degrees.

- Used in a low temperature (below 18° C) environment, the evaporator in a conventional dehumidifier (a dehumidifier with a compressor, hereinafter referred to as "conventional dehumidifier") is prone to frost or ice formation,

- Conventional dehumidifiers have their own defrosting function. Unless necessary, it is generally not recommended to use conventional dehumidifiers in low temperature environments.

- When using the dehumidifier, it should be noted that there should be no obstacles within 50cm in all directions around the air outlet and air inlet.

- Using the continuous drainage function, to ensure smooth drainage, no position of the water pipe should be higher than the water outlet of the dehumidifier.

- It is normal that the ambient temperature of the dehumidifier will rise during use.

- The use place of the dehumidifier should be relatively closed.

- When used under the conditions of low humidity and low temperature (ambient temperature <10° C and humidity <45%), the amount of dehumidification will be significantly reduced, or even no dehumidification, which is a normal phenomenon.

When the machine fails:

- Unplug immediately

- Troubleshoot according to the manual's troubleshooting methods

- If the fault cannot be solved according to the troubleshooting methods in the manual, please contact the dealer or manufacturer directly